電話:0755-86131192

郵箱:info@3doe.com

地址:深圳市龍華區民治大道民治商會大廈六樓

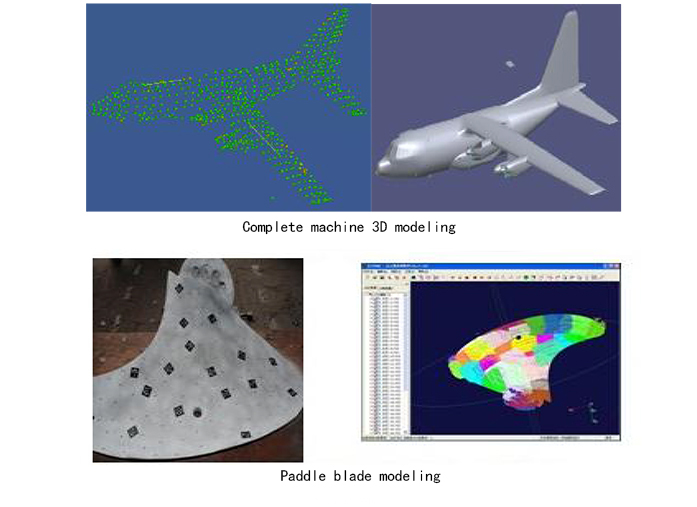

3DOE Metric 3D photogrammetry system Using ordinary SLR cameras (non-measurement cameras), through multiple two-dimensional photos, based on the principle of industrial close-range photogrammetry, reconstruct the three-dimensional coordinates of key points on the surface of the workpiece, which is widely used in the key points of medium and large (several meters to tens of meters) objects 3D measurement.

3DOE Metric 3D photogrammetry system Using ordinary SLR cameras (non-measurement cameras), through multiple two-dimensional photos, based on the principle of industrial close-range photogrammetry, reconstruct the three-dimensional coordinates of key points on the surface of the workpiece, which is widely used in the key points of medium and large (several meters to tens of meters) objects 3D measurement.

Product features :

Compared with the traditional three-coordinate measuring instrument, the system has no mechanical stroke limit, and is not limited by the size, volume, and shape of the measured object. It can effectively reduce the cumulative error and improve the measurement accuracy of the overall three-dimensional data. It can replace traditional laser trackers, articulated arms, theodolites, etc., and there is no tedious problem of moving stations, which is convenient for measuring large workpieces.

3DOE Metric 3D photogrammetry system composition

1. High-performance SLR camera

2. Coding mark points

3. Non-coding mark points

4. Ruler

5. Computer

6. Detection and analysis software, etc.

Technical advantages:

1. The first domestically developed industrial close-range photogrammetry system;

2. High-precision camera calibration algorithm, suitable for a variety of digital cameras;

3. The core algorithm of independent intellectual property rights has reached the advanced level of foreign countries;

4. Large measuring range: objects within the range of 0.3m~30m can be measured;

5. High measurement accuracy: the highest accuracy can reach ±0.015mm/m;

6. Fast measurement speed: convenient and fast taking pictures, fast calculation speed, 3D visualization of measurement results;

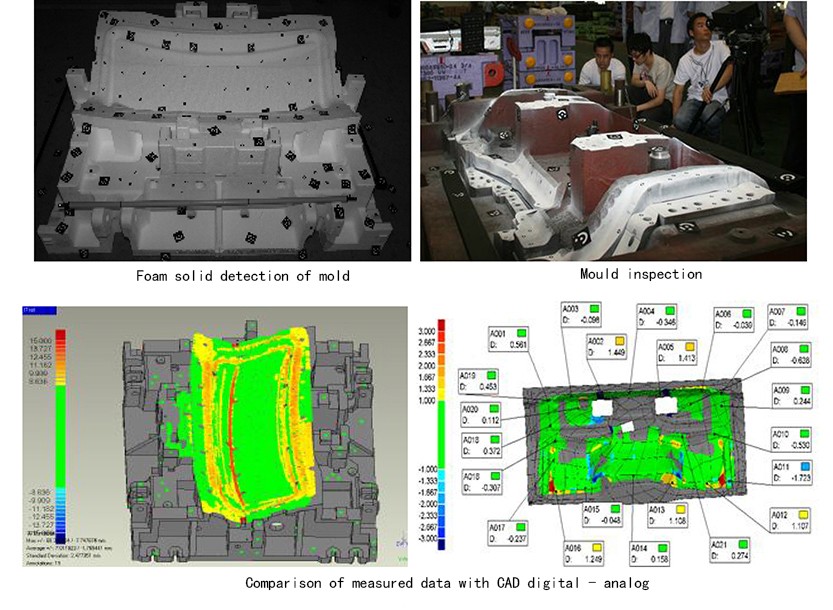

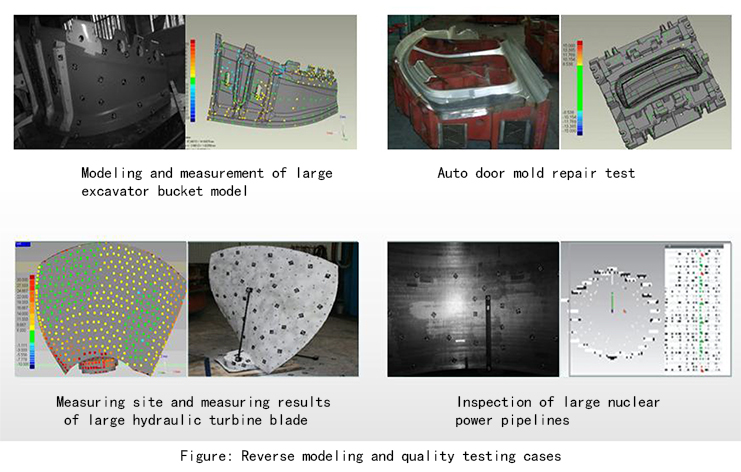

7. With CAD digital-analog comparison module, it can be used for quality inspection;

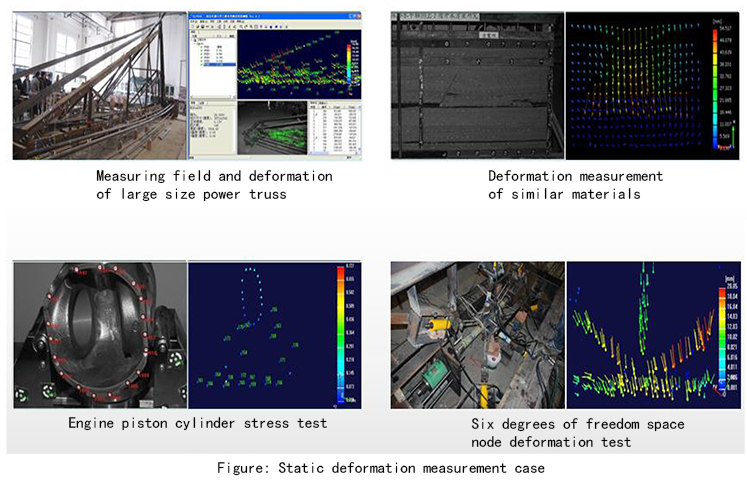

8. Equipped with a static deformation measurement module, which can measure the deformation data of the workpiece;

9. Convenient operation: The equipment does not need to be calibrated in advance, it is convenient to use, and has no special requirements for operators;

10. Strong adaptability: It is not restricted by the environment and measurement range, and can be measured in the workshop or industrial site;

11. Portable design: The device is light and portable, and a single person can carry it out to carry out measurement work.

Technical Description:

1. Core technology: industrial close-range photogrammetry

2. Measurement results: three-dimensional coordinates, three-dimensional displacement

3. Measurement format: support the measurement format of tens of centimeters to tens of meters

4. Measuring camera: support a variety of SLR, industrial camera image calculation

5. Number of cameras: support a single camera or multiple camera images to calculate at the same time, improve the measurement efficiency of large workpieces

6. Camera calibration: software self-calibration, supports a variety of camera lens distortion models

7. Measurement accuracy: up to ±0.015mm/m

8. Marking point type: support 10, 12, 15 code points, support white dots on black background, black dots on white background, more types can be customized

9. Static deformation analysis: by repeatedly measuring the three-dimensional coordinates of the observed landmark points under different deformation states, the key point three-dimensional deformation deviation calculation and chromatographic analysis can be carried out; the displacement measurement results are drawn in the form of rays and chromatograms in the three-dimensional view, and the true expression is Deformation and movement of 3D points

10. Three-dimensional digital model comparison: It can compare the three-dimensional geometric shape of the tested workpiece and the CAD digital model, and quickly and easily detect the product shape quality of large-scale workpieces. Supports stl, iges, step and other digital model file formats for comparison 3D color display of results

11. Thickness compensation function: with automatic compensation for the thickness of coded points and non-coded points

12. Coordinate conversion function: 321 conversion, reference point fitting, global point conversion, matrix conversion and other coordinate conversion functions

13. Element creation function: can create 3D points, lines, surfaces, circles, slots, rectangular holes, balls, cylinders, cones and other 3D elements

14. Analysis creation function: you can create a variety of analyses such as point-to-point distance, point-to-line distance, point-to-surface distance, line-to-line angle, line-to-surface angle, and surface-to-surface angle

15. Multi-core acceleration: multi-core CPU parallel operation to improve system calculation speed

16. System compatibility: compatible with 32-bit and 64-bit systems

? Classic cases

? Technical Parameters

Precision | ≤0.1mm/4m |

Measuring range | ≥4m 大型、超大型的工件(幾米甚至幾十米) |

Camera resolution | 18million pixels |

power supply | AC220±20%V, 50HZ or other meeting requirements |

equipment weight | 2KG |

Matching method | Fully automatic matching of code points |

Data transmission method | Flash card or wireless transmission |

Operating temperature | -20°~100°C |

Working humidity | 35%-70% |

Computer configuration requirements | Notebook or desktop computer |

To understand the specific application of 3D measuring head, blue light raster scanning, high-precision three-dimensional measurement, please contact online (leave a message) or call 0755-86131192!

Provide system customized solutions!