Metal casting is a process in which metal is smelted into a liquid that meets certain requirements and poured into a casting mold. After cooling, solidification, and cleaning, castings with predetermined shapes, sizes and properties are obtained. Because the casting blank is almost formed, it can achieve the purpose of avoiding machining or a small amount of processing, reducing the cost and reducing the time to a certain extent. Casting is one of the basic processes of the modern machinery manufacturing industry.

The problem

1. There is a prototype of a metal casting, but no metal casting mold, if it can be produced quickly.

2. How to quickly obtain 3D data of metal castings.

3. Metal castings have many detailed features, which must be scanned completely.

3D scanning reverse design and development of mold solutions for metal castings

The technical engineers of Jingyixun Technology use a camera-based 3D scanner (PTS-A series) to scan metal castings, quickly obtain 3D data of metal castings, and solve key industrial design problems in the manufacturing industry. Structured light 3D scanning technology greatly improves the level of mold production and mechanical manufacturing.

1. Preparation

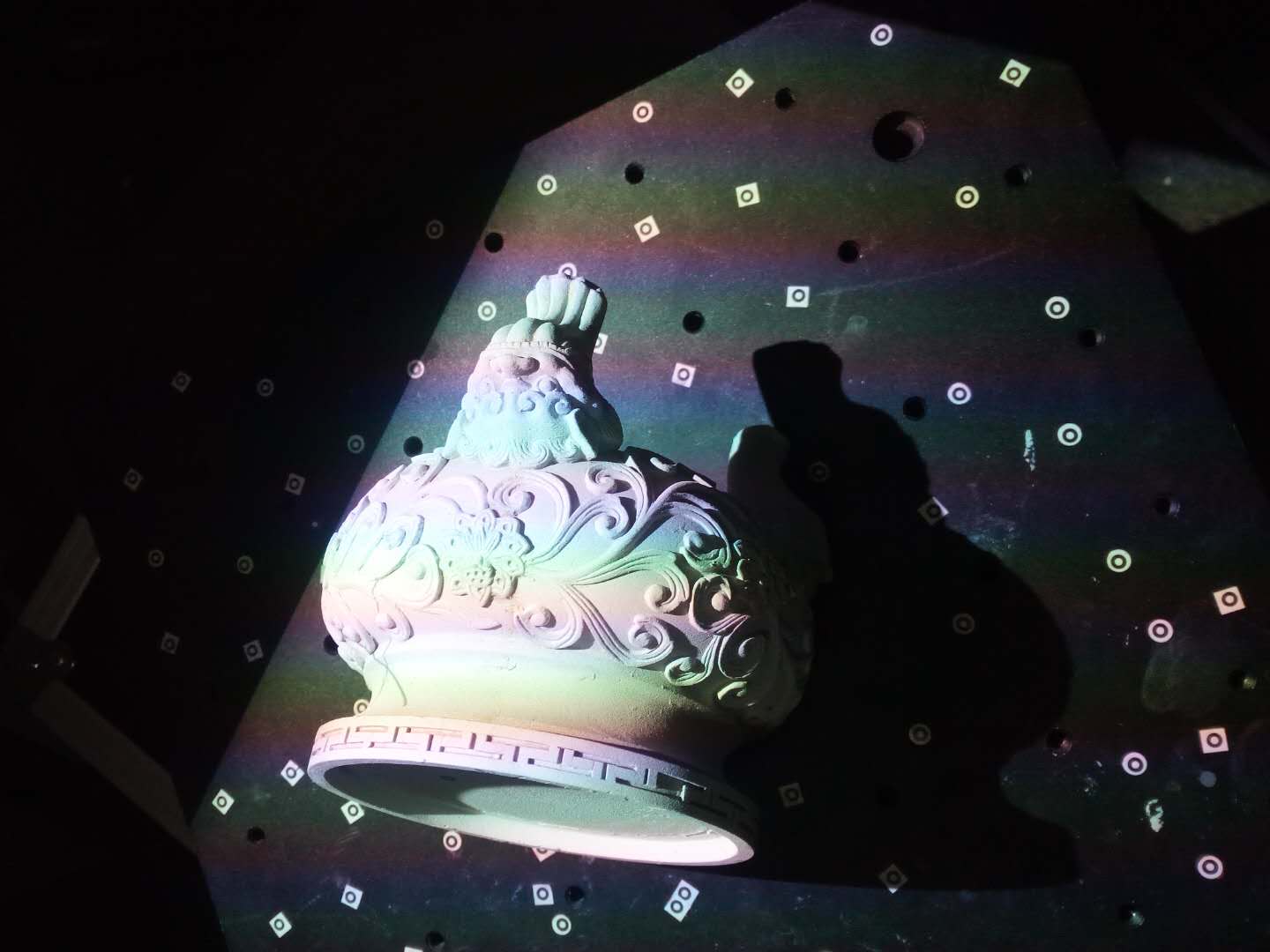

For our technical engineers to use industrial-grade 3D scanners, metal casting surface treatment and marking points, marking points are to ensure industrial-grade accuracy, preparation work takes about 2 minutes.

2. Scan metal castings

Photographic 3D scanner (PTS-A series) scans metal castings to quickly obtain 3D data of metal castings. The scanning process is visualized, and the scanning results can be directly seen. It takes about 15 minutes to scan a metal casting.

3. Reverse design of metal castings

After obtaining the 3D data of the metal casting, reverse design is carried out to obtain an accurate 3D data model, which can be used for 3D printing or open mold mass production

Highlights of the camera-based 3D scanner

1. Non-contact blue light 3D scanner

2. It can quickly obtain 3D data of the scanning robot shell

3. Can directly import 3D reverse software to draw pictures

4. Can be directly connected to a 3D printer

5. Fast speed and high precision

summary

The shape and structure of metal casting parts can be said to be complex, irregular and without reference features. 3D scanning of castings is still efficient and accurate measurement. The scanned data can be directly used for rapid prototyping and FEA finite element analysis, or combined with 3D design software to complete 3D scanning reverse design to provide data for mass production.

Related Products

PTS-A series (binocular) photographic white light 3D scanner PTS-A series (four - eye) photographic white light 3D scanner

0755-86131192

0755-86131192

0755-86131192

0755-86131192